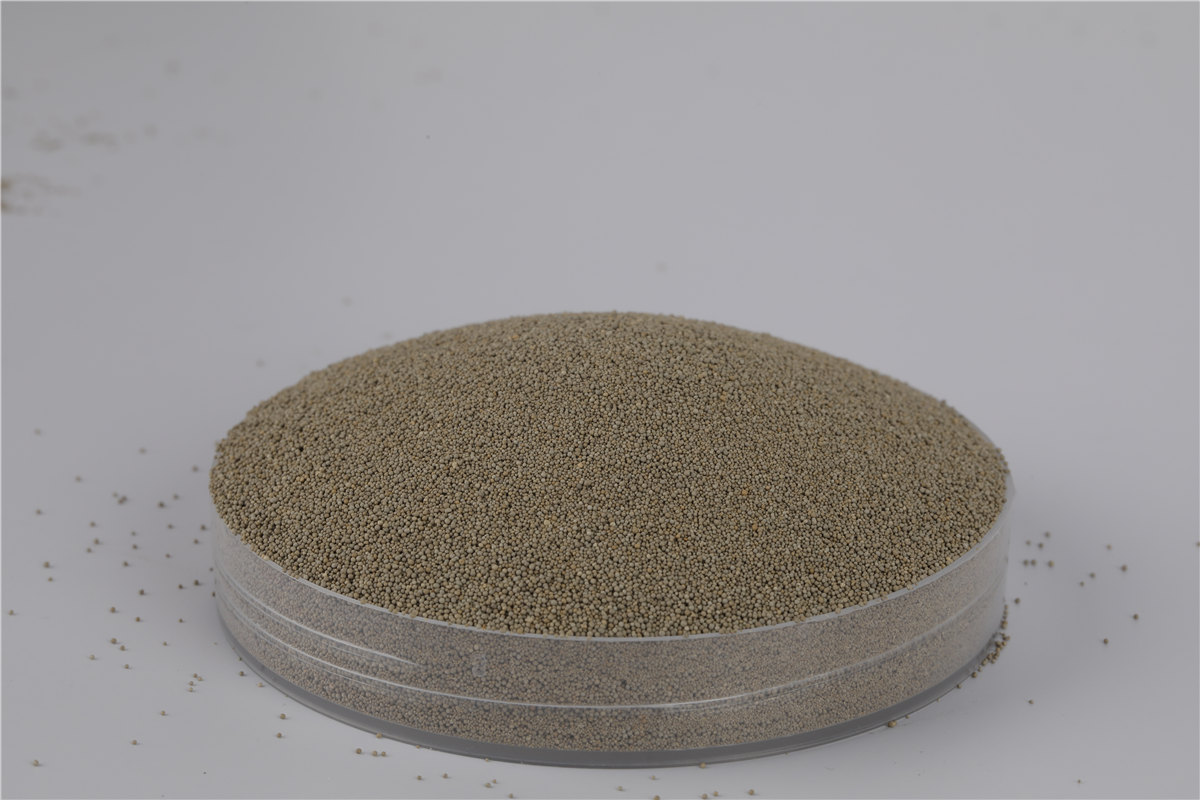

OEM/ODM Manufacturer Foundry Ceramic beads in China

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for OEM/ODM Manufacturer Foundry Ceramic beads in China, We promise to try our greatest to deliver you with premium quality and efficient solutions.

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Al2O3 sand, China ceramic beads, Each customer’s satisfactory is our goal. We’ve been looking for long-term cooperation with each customer. To meet this, we keep up our quality and deliver extraordinary customer service. Welcome to our company, we’ve been expecting to cooperate with you.

Features

• Uniform component composition

• Stable grain size distribution and air permeability

• High refractoriness (1800°C)

• High resistance to wear, crush and thermal shock

• Little thermal expansion

• Excellent fluidity and filling efficiency owing to being spherical

• Highest reclamation rate in the sand loop system

Application Sand Foundry Processes

RCS (Resin coated sand)

Cold box sand process

3D printing sand process (Include Furan resin and PDB Phenolic resin)

No-bake resin sand process (Include Furan resin and Alkali phenolic resin)

Investment process/ Lost wax foundry process/ Precision casting

Lost weight process/ Lost foam process

Water glass process

Ceramic Sand Property

| Main Chemical Component | Al₂O₃ 58-62%,

Fe₂O₃<2%, |

Al₂O₃ ≥53%,

Fe₂O₃<3.5%, |

Al₂O₃ ≥45%,

Fe₂O₃<4%, |

| Grain Shape | Spherical | Spherical | Spherical |

| Angular Coefficient | ≤1.1 | ≤1.1 | ≤1.1 |

| Partical Size | 45μm -2000μm | 45μm -2000μm | 45μm -2000μm |

| Refractoriness | ≥1800℃ | ≥1790℃ | ≥1700℃ |

| Bulk Density | 1.5-1.6 g/cm3 | 1.5-1.6 g/cm3 | 1.5-1.6 g/cm3 |

| PH | 7.2 | 7.2 | 7.2 |

| Application | Steel, Stainless steel, Iron | Carbon steel, Iron | Iron, Aluminum, Copper |

Grain Size Distribution

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | |

| #400 | ≤5 | 15-35 | 35-65 | 10-25 | ≤8 | ≤2 | 40±5 | ||||

| #500 | ≤5 | 0-15 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 | 50±5 | |||

| #550 | ≤10 | 20-40 | 25-45 | 15-35 | ≤10 | ≤5 | 55±5 | ||||

| #650 | ≤10 | 10-30 | 30-50 | 15-35 | 0-20 | ≤5 | ≤2 | 65±5 | |||

| #750 | ≤10 | 5-30 | 25-50 | 20-40 | ≤10 | ≤5 | ≤2 | 75±5 | |||

| #850 | ≤5 | 10-30 | 25-50 | 10-25 | ≤20 | ≤5 | ≤2 | 85±5 | |||

| #950 | ≤2 | 10-25 | 10-25 | 35-60 | 10-25 | ≤10 | ≤2 | 95±5 |

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for OEM/ODM Manufacturer Foundry Ceramic beads in China, We promise to try our greatest to deliver you with premium quality and efficient solutions.

OEM/ODM Manufacturer Foundry Ceramic beads in China, Each customer’s satisfactory is our goal. We’ve been looking for long-term cooperation with each customer. To meet this, we keep up our quality and deliver extraordinary customer service. Welcome to our company, we’ve been expecting to cooperate with you.