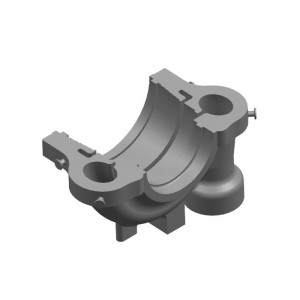

Metal Sand Casting Parts for Medium Pressure Inner Cylinder Steam Turbine

Detailed Description

We specialize in providing a broad selection of Steam Turbine Castings that are created by technocrats with in-depth technical knowledge of various turbine components. They are quite practical and simple to install.

Production Process:

Resin sand casting process

Production Capacity:

Casting/ Melting/ Pouring/ Heat Treatment/ Rough Machining/ Welding/ NDT Inspection (UT MT PT RT VT)/ Packaging/ Shipping

Quality Documents:

Size report.

Physical and chemical performance report (including: chemical composition/ tensile Strength/ yield strength/ elongation/ reduction of area/ impact energy).

NDT test report (including: UT MT PT RT VT)

Advantage

As a leading supplier of metal sand castings, we are proud to present our Medium Pressure Internal Steam Turbine Castings. Our experienced technocratic team manufactures these castings with in-depth technical knowledge of various turbine components, ensuring their quality and reliability.

Our medium pressure inner casing turbine castings are designed to provide exceptional performance and reliability in harsh and demanding environments. They are built to withstand the rigors of use in a wide variety of industrial environments, from power generation to heavy machinery.

Whether you are looking for a cost-effective and reliable solution to your turbine needs, or need a reliable and long-lasting replacement part, our medium pressure internal steam turbine castings are the perfect choice. We stand behind the quality and reliability of our products and are committed to providing the best service and support to our customers.

FAQ

1. What are your prices?

Our prices are subject to change depending on the casting material and property and other market factors. Certainly, factory price and high quality is guarantee. We will share you an updated price list after your company contact us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Quality documents, Insurance; Original of certification, and other export documents where required.

4. What is the average lead time?

Generally is 2-3 months.

5. What kinds of payment methods do you accept?

You can make the payment to our bank account by TT/ LC: 30% deposit in advance, 70% balance against the copy of B/L.