Low MOQ for KOCEL Customized Sand 3D Printer & Auto Spare Part Sand Mold by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining Cylinder Head

Our commission is to serve our users and purchasers with greatest good quality and aggressive portable digital items for Low MOQ for KOCEL Customized Sand 3D Printer & Auto Spare Part Sand Mold by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining Cylinder Head, With us your money in secure your business in protected . Hope we can be your trustworthy supplier in China . Wanting forward for your cooperation .

Our commission is to serve our users and purchasers with greatest good quality and aggressive portable digital items for China Sand Core and Sand, We’ve a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

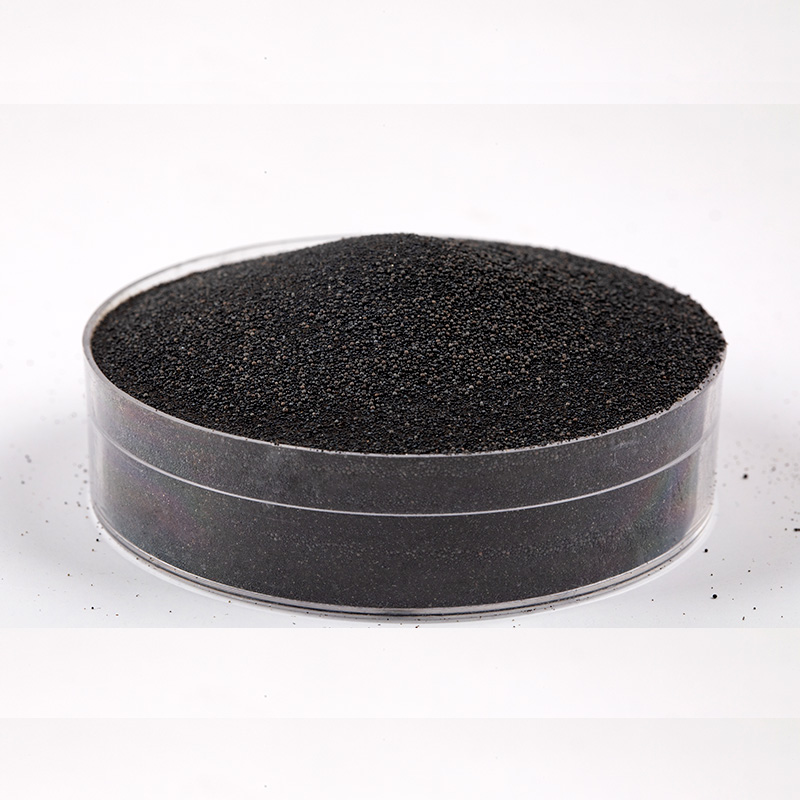

Features

• Uniform component composition

• Stable grain size distribution and air permeability

• High refractoriness (1825°C)

• High resistance to wear, crush and thermal shock

• Little thermal expansion

• Excellent fluidity and filling efficiency owing to being spherical

• Highest reclamation rate in the sand loop system

Application Sand Foundry Processes

Resin coated sand process

Cold box and warm box sand process

3D sand printing process

No-bake resin sand process (Include Furan resin and Alkali phenolic resin)

Investment process/ Lost wax foundry process/ Precision casting

Lost weight process/ Lost foam process

Water glass process

Ceramic Sand Property

| Main Chemical Component | Al₂O₃ 70-75%,

Fe₂O₃<4%, |

| Grain Shape | Spherical |

| Angular Coefficient | ≤1.1 |

| Partical Size | 45μm -2000μm |

| Refractoriness | ≥1800℃ |

| Bulk Density | 1.8-2.1 g/cm3 |

| PH | 6.5-7.5 |

| Application | Steel, Stainless steel, Iron |

Grain Size Distribution

|

Mesh |

20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | Pan | AFS Range |

|

μm |

850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | |

| #400 | ≤5 | 15-35 | 35-65 | 10-25 | ≤8 | ≤2 | 40±5 | ||||

| #500 | ≤5 | 0-15 | 25-40 | 25-45 | 10-20 | ≤10 | ≤5 | 50±5 | |||

| #550 | ≤10 | 20-40 | 25-45 | 15-35 | ≤10 | ≤5 | 55±5 | ||||

| #650 | ≤10 | 10-30 | 30-50 | 15-35 | 0-20 | ≤5 | ≤2 | 65±5 | |||

| #750 | ≤10 | 5-30 | 25-50 | 20-40 | ≤10 | ≤5 | ≤2 | 75±5 | |||

| #850 | ≤5 | 10-30 | 25-50 | 10-25 | ≤20 | ≤5 | ≤2 | 85±5 | |||

| #950 | ≤2 | 10-25 | 10-25 | 35-60 | 10-25 | ≤10 | ≤2 | 95±5 |

Our commission is to serve our users and purchasers with greatest good quality and aggressive portable digital items for Low MOQ for KOCEL Customized Sand 3D Printer & Auto Spare Part Sand Mold by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining Cylinder Head, With us your money in secure your business in protected . Hope we can be your trustworthy supplier in China . Wanting forward for your cooperation .

Low MOQ for China Sand Core and Sand, We’ve a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.