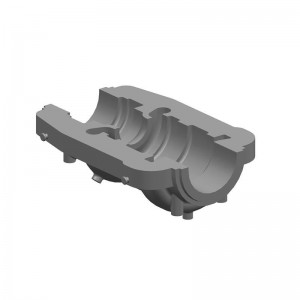

Steam turbine sand casting

Detailed Description

Production Process:

Resin sand casting process

Production Capacity:

Casting/ Melting/ Pouring/ Heat Treatment/ Rough Machining/ Welding/ NDT Inspection (UT MT PT RT VT)/ Packaging/ Shipping

Quality Documents:

Size report.

Physical and chemical performance report (including: chemical composition/tensile Strength/yield strength/elongation/reduction of area/impact energy).

NDT test report (including: UT MT PT RT VT)

Description

We specialize in providing a broad selection of Steam Turbine Castings that are created by technocrats with in-depth technical knowledge of various turbine components. They are quite practical and simple to install.

Advantage

Introducing the top-of-the-line high-pressure inner cylinder for steam turbines. Constructed from the highest quality ZG15Cr2Mo1, ZG15Cr1Mo1V, ZG15Cr1Mo1, ZG13Cr9Mo1VNbN and ZG13Cr10Mo1WVNbN materials, this product is designed to withstand high pressure steam turbine operation without failure.

Our steam turbine high pressure inner cylinders range in weight up to 10,000 kg and can be tailored to meet your specific requirements. We pride ourselves on offering a fully customizable service, ensuring our clients receive the best possible product.

The steam turbine high pressure inner cylinder is a sand cast product engineered to ensure exceptional durability and reliability. Products are manufactured in accordance with the strict quality standards set forth in ISO9001-2015 certification, and our skilled technicians work tirelessly to ensure that each product meets or exceeds customer expectations.

When it comes to packaging, we understand that our customers' needs vary. That's why we offer flexible packaging services, where items are packed according to our customers' specific requirements. Whether you need boxing, palletizing or crating, we'll make sure your product arrives safely at its destination in the best possible condition.

The steam turbine high pressure inner cylinder casting is manufactured in China, a country known for its engineering and technical expertise. This means you can rest assured of the quality and reliability of your product, knowing it was made by the best technicians in the industry.

FAQ

1. What are your prices?

Our prices are subject to change depending on the casting material and property and other market factors. Certainly, factory price and high quality is guarantee. We will share you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Quality documents, Insurance; Original of certification, and other export documents where required.

4.What is the average lead time?

Generally is 2-3 months.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account by TT/ LC:

30% deposit in advance, 70% balance against the copy of B/L.